The carriage is belt driven unit with stepper motor at one end and idler gear at the other end. We discuss the design of the idler in this post.

Overall Design features

The idler gear has evolved considerably, especially since the alignment issues. We use:-

- Bearing enclosure (3-D print)

- Two sealed bearing (Metric, 6mm bore)

- 1/4″ Aluminum axle, sanded at each end to accept the Metric (6mm) bearings

- 3-D printed gear

- Two large washers

- Two smaller washers.

These components are then attached to Aluminum right-angle bracket that is secured to the 1010 bar at the end of the winder.

The Bearing Enclosure

Below is a 3-D view of the Bearings enclosure.

WP 3D Thingviewer Lite need Javascript to work.

Please activate and reload the page.

One can see where the 2 bearings are mounted. This is interference fit. There are three holes which are used to attach this to a aluminum bracket. One can tighten these three bolt/nuts to increase tension in the belt and we can adjust as required to balance the belt.

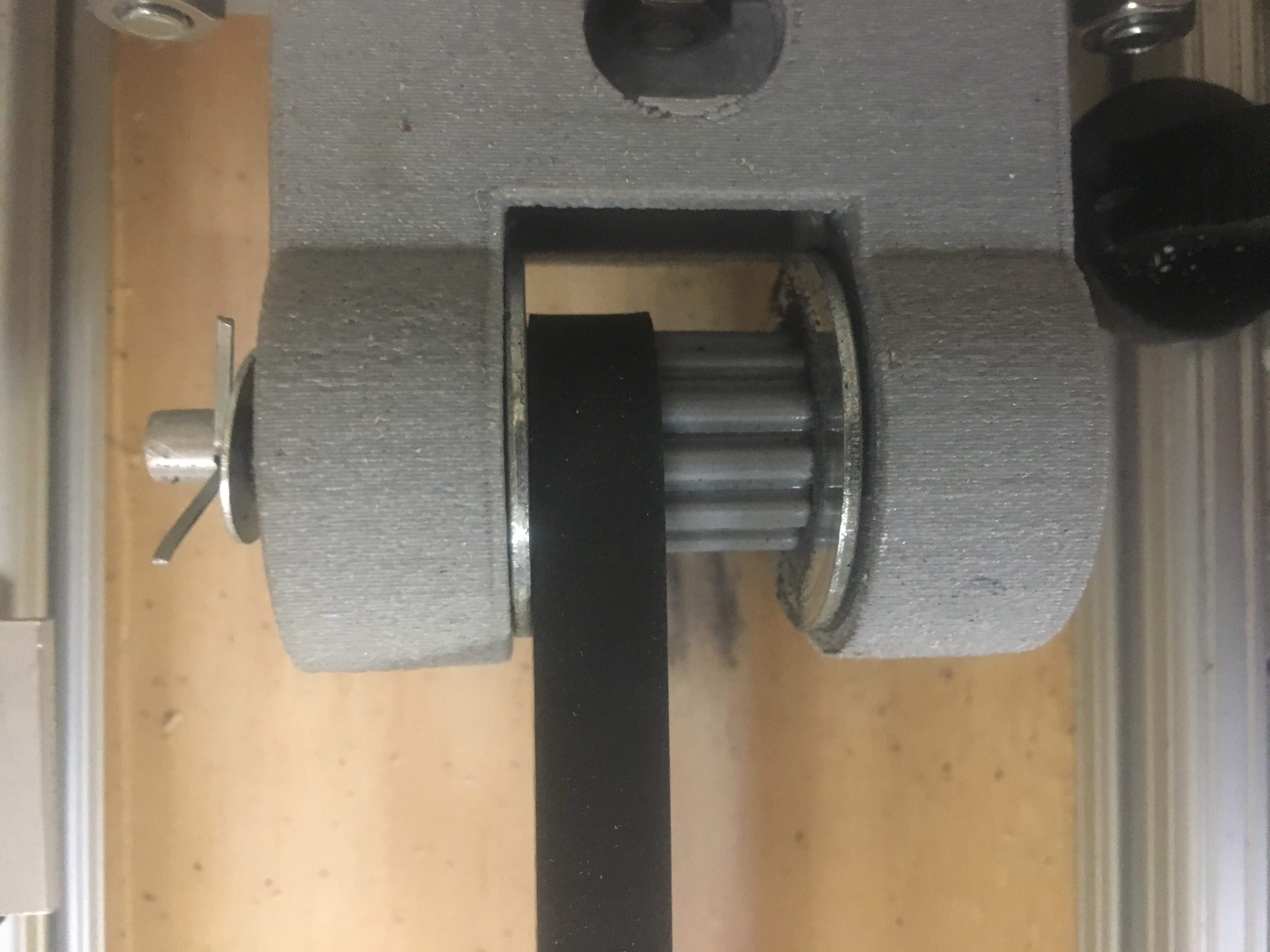

We have sufficient gap between two bearing compartments for ~22mm gear and several washers to assure there is no belt/ABS plastic abrasion.

The Gear

We purchased several gears, but had problems getting them working – some gears where duds and other gears had holes drilled in them that were not working. In the end, I printed a Gear. A lot of effort went into this gear – mostly trial and error.

Below is what we printed.

We also extended the ABS out a little on each side (the green area) to ensure that any abrasion did NOT occur on the gear teeth. The reasoning is that if we don’t, the teeth will deform from heat and this will help degrade the belt teeth.

After we print it, we treat it with acetone. This hardens and smooths the surface which is EXTREMELY important to preserve belt life.

Everything connected

Below is a photo of all the parts connected and working together.

Issues Identified

Destruction of the idler gear

I have noticed that after some use of the winder, a grey powder is being deposited at one end. Please see below.

At first I thought this might be the belt, but now I suspect it is these “end” pieces that are grinding away. For this reason, I think I’ll need to replace the idler gear occasionally, e.g. every 1 or 2km of filament.

The Belt

The belt ideally would sit in the middle, but it doesn’t. Instead it sits at one end. We can adjust screws to the back of the idler to encourage it to move in one direction, but it eventually goes back to the LEFT position.

I have thought of having fixed guards and this MIGHT be the way to go, however concerns with belt abrasion against the gear have put me off this. For now, we have stainless steel washers to reduce chance of abrasion of belt. So far it has worked well.