I have checked the steps many times over several days, trying to make very sure I have not mis-understood anything, measured anything incorrectly, missed any steps that might be good to do now.

I then performed several dummy (pretend) attempts at gluing the motor mount into the Airframe, to help me anticipate any potential issues and also have the best procedure to glue this motor mount into the Airframe. I was able to confirm that I could see where the glue was in relation to the lines inside the air-frame.

I made two batches of araldite actually. Wanted to make sure I had more than enough glue.

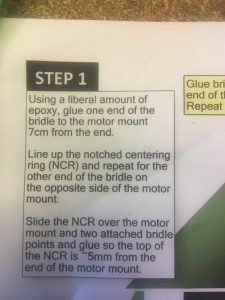

I put glue on the stick end and turned in my hand as I put it down in between the two lines. I used the cut-out in air-frame (for the fins) to ensure I got the glue in the right spot. The occasional motion of the air-frame stopped glue from dripping from the edge and allowed me to paste a nice layer of araldite in the air-frame. Then I loaded the motor mount and twisted in back and forward to ensure the glue was spread about in between the centering ring and the air-frame.

Then I put the whole rocket into the vertical position as shown below:-

The glue requires 24 to 72 hours to completely cure. So we will give it the complete 72 hours (Sunday 09:30 to Wednesday 09:30). We want the BEST possible result

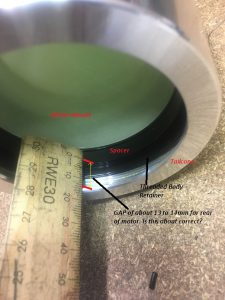

We checked that the motor mount was indeed sitting 27mm outside the end of the Air-frame. See the photo below.

I had a look from the top to see how it looked.