After the massive issues with the previous wind – not being able to remove the tube, I decided drastic changes needed to occur.

The aim is prepare Mandrel so we do NOT need to use Dry Ice to remove it.

The Solution

The Solution is several fold: –

- Do not heat the shrink tape for more than 10 minutes. This will ensure we don’t accelerate curing excessively, and we still get a chance to squeeze out excessive Epoxy

- We use a combination of Mould Release Wax and a “lubricant” to make removal easier.

- Only let the Curing go for as long as required before removal. i.e. after 6 hrs (guess), remove the tube. i.e. Don’t wait 12 hours.

We look at each of these points in more detail below.

Shrink Heat Tape

The curing occurs faster as you heat the epoxy. As the Epoxy cures, it shrinks and gets ever harder to remove from the Mandrel. Why I had to heat it for 4 hours is beyond me. All I wanted to happen is for the Excess Epoxy to be squeezed out. After ~10mins, the Epoxy is not fluid enough to be squeezed out, so the heater should be turned off and Mandrel be allowed to rotate for several hours

Surface Preparation

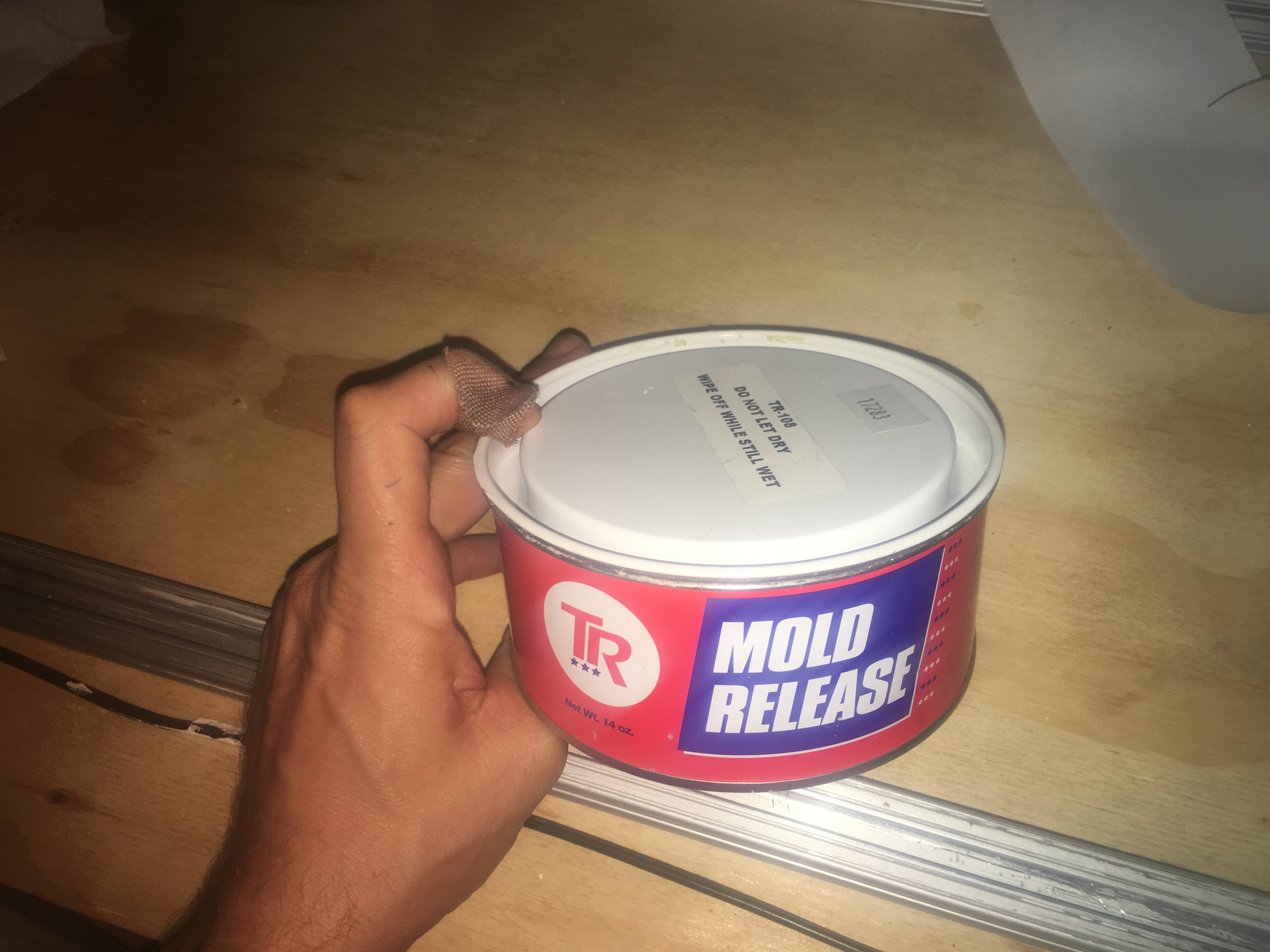

I wish to use TR-108 – a wax that is applied to the mandrel.

The lubricant I wish to use is Graphite (product from Bunnings)

The steps I followed on the next test run are:-

- Water/sand from 400 grit down to 2000grit

- Use Methylated spirits to clean surface

- Use Brasso with paper towel to produce finer finish

- Use Methylated spirits to clean surface – Do this a number of times to get VERY clean

- Apply 7 coats (1 hr in between) of TR-108. I would apply thin film with clean paper towel, from one end to the other. When I finish, I go back the beginning end with a CLEAN cloth and polish. I polish three times, each time with a new Clothe. That is ONE layer done

- The next day I do ONE more coat of TR-108 wax – same procedure.

- Next I get some Graphite (powder) and sprinkle over entire Mandrel.

Below is a photo of Mandrel with 7 of the 8 coats of Wax applied.

I’m very happy with how it is going, but won’t be sure of effectiveness until we have to take the carbon fiber tube off.