This post is a little late, but still worth getting out.

On the 10th of January 2016, myself, Anna, Jeremy, Isaac and “Grandpa Val” travelled to the Goldcoast to attend a Queensland Rocketry Society Launch day. We all got to fly a rocket! Even Anna did!

Isaac’s Rocket

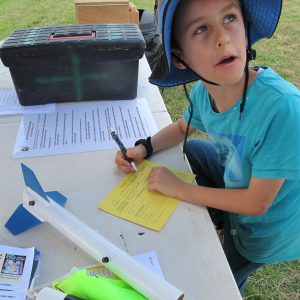

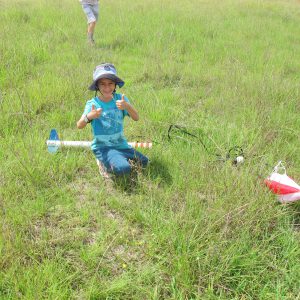

Isaac flew a Small 15 Gram model rocket with a B-Engine. He was initially very scared of the noise and wanted to sit further back with the cars. Eventually he got the courage to participate in the rocket launching. Very pound of you Isaac!

Here are some pictures of Isaacs rocket and the boy himself!

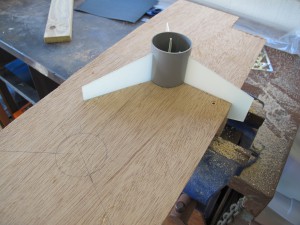

Jeremy’s Rocket

Jeremy’s rocket is an exceptional rocket for a first timer. This rocket had a D-engine expertly installed by Blake (Owner of Ausrocketry). It deployed its parachute perfectly! Lovely work Jeremy!

Anna’s (Mummy) Rocket (UFO)

Anna couldn’t miss out on the action and launched a UFO rocket. This had a C-Engine in it. It flew really well!

Joe’s L1 Attempt

Well I decided to go for my L1. This was very exciting. It took a lot of time to set-up the engine, even though it was just a CTI engine! I was taking things very carefully. Didn’t want to make any mistakes.

What a great day!