I received the Raven3 Altimeter, Shockcord, parachute bags and the RBF tag and so thought I should start installing the Avonics bay Electronics.

The thought process

Normally, one would expect that installing the electronics would be easy to do. Just mount battery, mount the Altimer, run some wires using cable ties, etc. But, more thought is involved in terms of placement. So I spent much time playing around with places to put the components.

I also had to decide a few other things:-

- How to construct the switch

- What type of battery to use

- The type of wire to use.

Switch

I decided to use a 10amp/250volt (AC) switch. This _should_ do the job, though I get the feeling that with DC voltages, it might not be as robust. That is okay, I will many tests to see how it fairs with setting off igniters.

Battery

I was going to use a LiPO battery, because they are so much more efficient than standard batteries. However I realised a LiPo does pose other issues. One being that I might need two LiPo batteries to supply required current and that I might have shipping/logistic issues with LiPo. So in the end, I decided to go for a 9 volt battery. I’ll probably use a Li/Mn Energizer battery (one of the blue ones).

Again, tests will tell me if my decision was a good one.

Wire

for the igniter wire, I choose wire that is rated 7.5Amps. This should be more then ample. I don’t expect it to pass this much current before the igniter does its job. I got twin wire (in a sheath). It makes for a neater job. This wire also fits inside the terminal block on the Raven 3 board. Very important!

Junction point

I wanted a 4 way splitter to allow the distribution of +9 volts to the igniters and the Raven 3. So I purchased 3×2 and used copper hook-up wire to link all three together.

Dean-Plug

I need to be able to disconnect the bulk-head without taking wire out of the terminal blocks mounted to the Bulkheads. I did this by installing a Dean-Plug. Then I’ll use a small cable-tie to ensure they don’t separate in flight.

Heat-Shrink

I wanted to guard against wires rubbing against the threaded rods and I wanted to reduce chance of shorts, so i employed heat-shrink over the rods. I didn’t bother to “shrink it” with heat, because I might want to remove them easily.

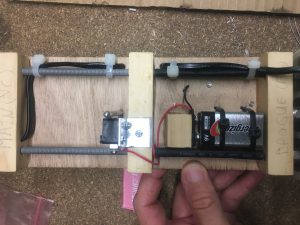

Here are some pictures of the Avionics bay

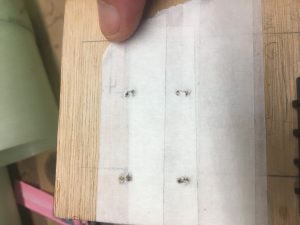

Using masking tape to improve quality of holes when drilling through plywood.

Here are a list of things that I did to ensure a good build:-

- Put in Witness marks so I know how to assemble it back together, with everything in the right spot. This is very important for the Remove Before Flight Pin. We needed to align the Vent hole with the Pin hole.

- The switch mounted to the Aluminium bracket is on a slight angle. This is done this way so that we have optimum lever position when pin is inserted. i.e. it is undeniably in the closed position

- We have rounded the end of the pin – hemispherical. This is to make pin/switch work better

- While the hole in the wood that the pin is pushed through is big enough for a loose fit, this hole was NOT done all the way. Part of the hole is a close fit, which means that the pin doesn’t just fall out. This is very important. We don’t want the system to be accidentally armed

- With all screw/nuts, I used Loctite equivalent to ensure screws don’t accidentally come off!

- For the 9 volt battery, I am using a higher quality clip, to reduce chance of failure here

- For screw on to the switch, I’ve made up my own eye connectors using copper. I’ve bent the far end down a little to reduce chance of wire/insulation being ruined. I’ve applied plenty of solder to ensure a good connection and I’ve finished it off with some araldite to ensure that the soldered connection isn’t taking physical load.