Keeping a rocket pointed up when launched from a balloon is not an easy feat. Countless hours of thought have been put into this and several ideas have been considered and then dismissed. Some of these ideas are presented below.

Have a rocket with Long Launch Rod

Can we use a launch rail, like we do on Earth?

No.

We need to first realise that while there is very little air at an altitude of 30km, there is still sufficient air to allow stabilisation using fins. This is provided we are travelling fast enough. The reduced air density means that the velocity required is substantially more then at sea level. This means we would need a longer launch rail to ensure that the velocity is sufficiently great when it leaves the rail tip. Let’s consider the equations that give us lift.

Lift = Cl * density x Velocity ^2 * Area/2

Density of Air at sea level is 1.225 kg/m^3

Density of Air at 30km is is 0.01841 kg/m^3

Let’s assume that 20ms-1 is the minimum velocity required at sea -level. With this we can estimate the minimum speed required at an altitude of 30km

velocity = sqrt(density-at-sea-level * velocity-at-sea-level^2/density-at-30km)

= 163ms-1

Let’s assume the rocket is accelerated at 10g (98ms-2) up the rail.

v = a * t

t = 163/98 = 1.66seconds

s = 0.5 * 98 * 1.66^2 = 135 metres

This is clearly impractical. The launch rod would be very long, heavy and unwildy. We would need a massive balloon and someway to stabilise the rod. Then we would have the issue of the launch rod coming back to Earth. Totally out of the question!

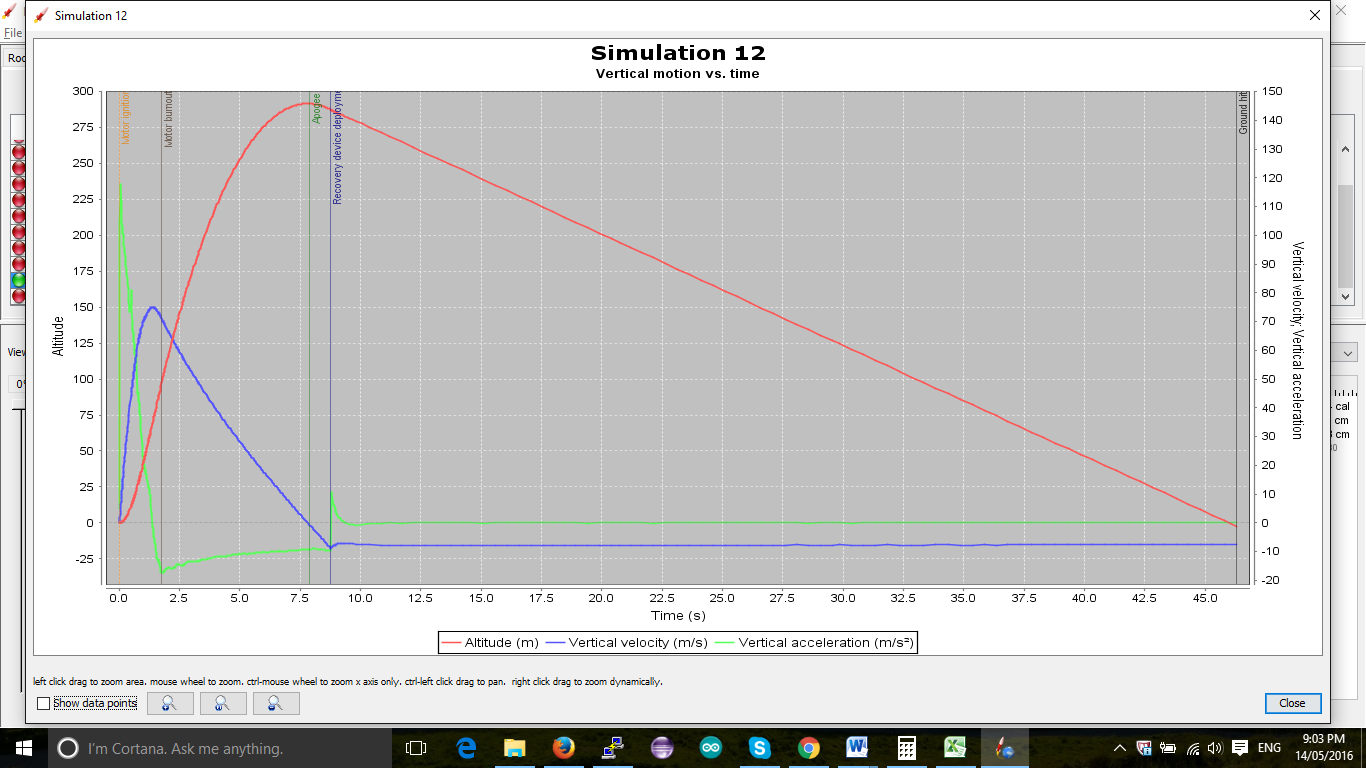

Spin stabilisation

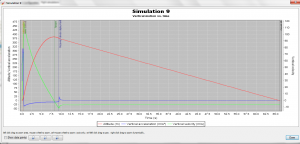

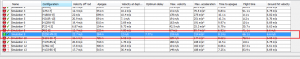

Another option considered was spin stabilisation, where by we attach rockets to the side to spin it up. This makes the rocket act like a spinning top. Simulations have been done to see how attaching two D-engines to a rocket, to see how fast it will get and how much the spin is affected when engines are slightly mis-aligned. Unfortunately. even with very small manufacturing tolerances there is sufficient wobble to cause issues. We tried to increase the Moment of Inertia in in some axes to reduce the amount of rotation in those directions, however this adds alot of extra weight which is extremely undesirable. There is also the problem of how we suspend the rocket when we spin it up, or if we have to release the rocket and then spin up.

This solution is extremely unpractical and complictes the launch sequence considerably. There a lot more possible modes of failure.

We have decided against this option.

Thrust Guided Rocket

The idea here is that one can either:-

– Move the nozzle, which will adjust the thrust direction

or

Move some vanes that are downstream of the thrust that re-direct the thrust direction

With the solid engines, the former is inpractical. The nozzles are fixed.

With the latter, the design is not simple, or easy to simple and some of the engineering required is not so simple. We would need some external actuators, ones that can provide a massive torque (to combat the force of the rocket thrust), while still keeping the rocket streamline, and at the same time using the limited ‘realestate’ at the bottom of the rocket. For the vanes, we would need special material that would not be destroyed by the thrust, be light and have a specific design to induce the right sort of adjustments.

We have decided against these two options.

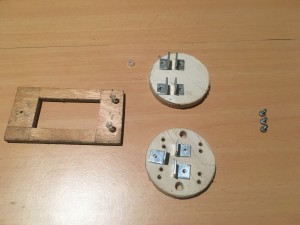

Centre of Mass Guided Rocket

This is not a commonly used method, however, it has been mentioned a little in some of the rocketry literature on the Internet. The concept is that you adjust the Centre of Mass (moving it laterally) so that the thrust, in combination with this off-axis centre of Mass produces a resultant moment.

Imagine yourself standing up and someone pushing you backwards. You instinctively put your arms/hands outreached in front of you to try and move your Centre of Mass forward.

This method could work, but it would need to move masses quickly and efficiently without producing too much un-wanted disturbances to the rocket’s motion. The whole system would need to be relatively light, so as to not be a burden on the rocket.

Summary

The latter option seems the most likely to succeed. We have decided to put a more thought into such a solution. In particular, we decided it would abe a good idea to try and simulate such an engine.